Auf dieser Seite finden Sie die ausstellenden Unternehmen der PARKEN 2025. Die Ausstellersuche gibt Ihnen frühzeitig einen Überblick über die teilnehmenden Unternehmen sowie deren Produkte und wird regelmäßig aktualisiert.

Quarrata Forniture S.r.l.

Adresse

Quarrata Forniture S.r.l.

Via Giovanni Palatucci 40/42

51039 Quarrata Pistoia

Italy

Telefon+39 0573 73294

Fax+39 0573 72055

Entdecken Sie mehr von uns

Über uns

Quarrata Forniture is a well established production reality based in Quarrata, Tuscany. Our company has been active in the market since 1994, designing and manufacturing machines for several sectors, though our core business remains automatic gluing solutions for mattresses production.

As machines producers, we combine the Italian heritage of craftsmanship with the most advanced and sustainable industrial production guidelines.

Through our constant activity of research and development, driven by our customer’s needs, we have redefined the technological standards of the industries where we compete with our machines.

Since 1994 our company have been involved in the design and production of cutting edge technology machineries for mattresses and pillows industry, developing breakthrough innovations for:

- High precision Water Base 1component adhesive roll application

- Water Based adhesive drying for zero-waiting time and straightaway in-line production

- Hot Melt application

- PCM application and drying

- Cushion and Pillows filling machines

- Fiber/Textiles/Foam recycling machines

Together with our sister company QF Engineering & Services we are focusing more and more in developing highly automated and flexible production systems.

Unsere Produktgruppen

Keywords

- Mattresses production

- Textile

- Cushion Pillow industry

- Fiber processing machines

- Machinery

Unsere Produkte

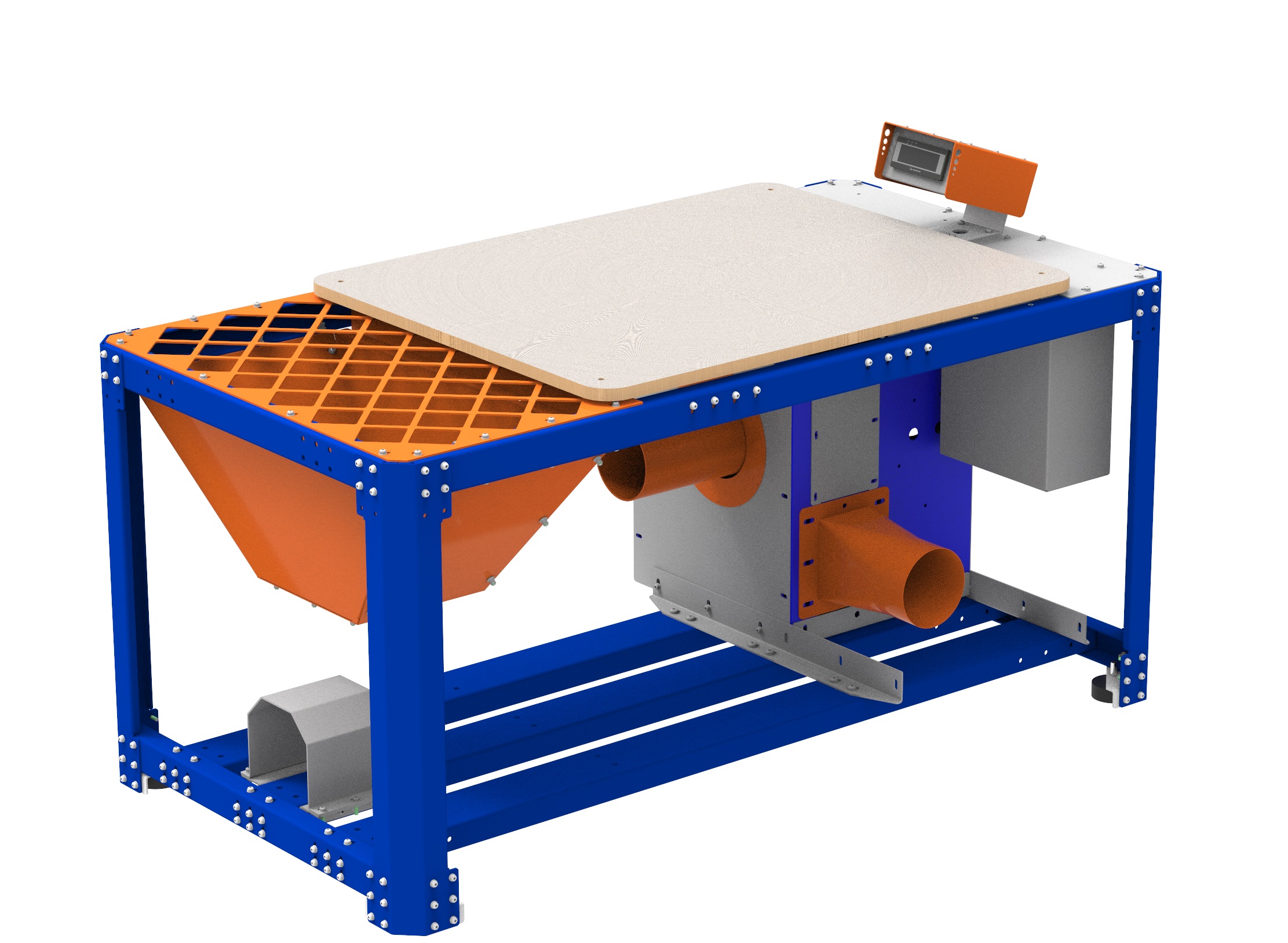

Kilo

The Kilo machine is a scale table conceived to standardize the cushion\pillow production easily controlling the weight of each piece. The machine is also equipped with a system which drives back to the storage (Silo) the material which during the filling may go out – to avoid any material loss. A possible upgrade enable the systems to stop the blower upstream once a specific target is reached during the filling.

Technical characteristics:

Dimensions: 170 x 190 cm

Height: 130 cm

Weight: 160 kg

Motor: 0,35 kw, 230V monofase

Display: 24VDC

Sensor scanning: 5 gr

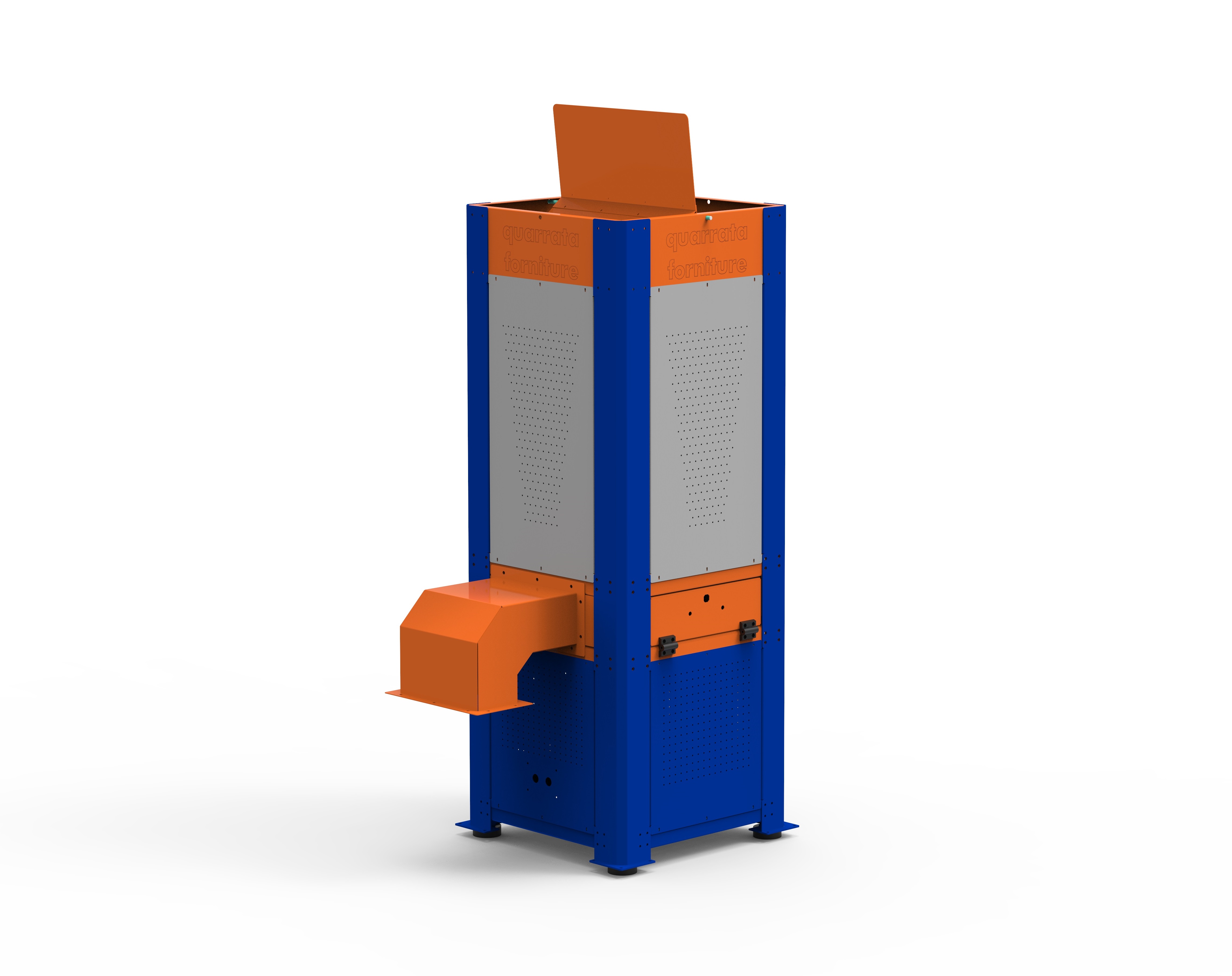

Grizzly

Grizzly is an electric shredding machine, designed to shred waste polyurethane foam and foam rubber, permitting both savings (recycling of materials used for filling) and reduction in waste to dispose of. The shredded material is expelled from the front outlet and can be collected in containers or transported, using an appropriate conveyor to storage Silo.

The size of the chips of shredded material can be adjusted using the outlet grates, available in 3 different sizes (10/15/20 mm) and also made on request. The outlet spout, the height of the conical conveyor and the revolving feed blade, guarantee that the machines operates in conditions of maximum safety.

TECHNICAL CHARACTERISTICS:

Height: 180 cm

Depth: 100 cm

Width: 75 cm

Weight: 115 kg

Working: electric

Motors: Three-phase 220/380 V 5,5 hp

Three-phase 220/380 V 10 hp

Three-phase 400 V - 14 hp

Safety equipments: automatic overload cutout, minimum

tension trip coil, emergency stop button

Grids available: 10, 15, 20, 25 mm

Production: 80kg/h (10 hp),

120 kg/h (14 hp), 250Kg/h (25Hp)

(approximate data)

Dumbo

Dumbo is an electric machine for filling cushions with short fiber materials like feathers,polyurethane foam chips, wool, resin-bonded products, composites etc. Dumbo can be used both directly connected with sacks containing the filler or with a storage Silo.

The new version of our Dumbo has slots at the level of the fiber exhaust pipe which allows you to choose the angle of the same union at user's choice and ease. This new modification maintains the maximum speed and ease of use, combined with extreme precision and uniformity of coverage. On customer's request, it's possible to install a speed controller that allows to increase or decrease the rate of filling of the cushions. The machine is equipped with a pneumatic gate valve that permits instant, accurate control when filling cushions.

TECHNICAL CARACTERISTICS:

Dimensions on floor: 80 x 110 cm

Height: 145 cm

Weight: 120 kg

Working: electro pneumatic (electric motor +

pneumatic valve)

Motor: threephase 220/380V, 1,5 kw

Safety equipment: automatic overload

cutout, minimum tension, trip coil,

emergency stop button

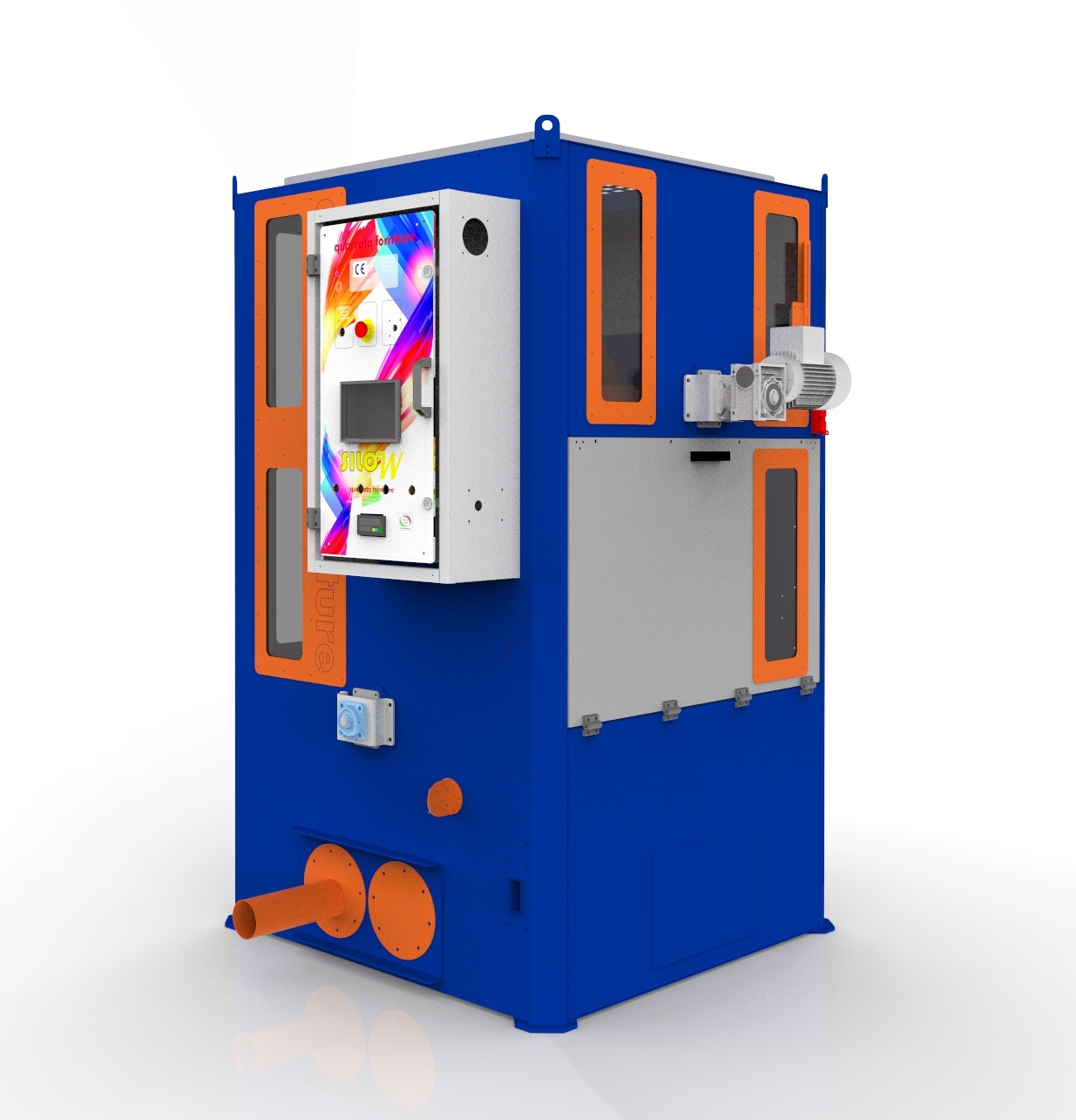

Silo

Our Silo machine is the best solution to optimize the filling systems of cushions for furniture, sofas and armchairs and ensure a constant inflow and continuous filling machines by reducing the processing time, and allow for mixtures of different materials. The Silo works with all filling materials such as wood chips of foam, ribbon, feathers, etc... Our Silo manage to mix the materials and automatically supply them to our filling machine Dumbo, but Xperform version limits fiber stress drastically. This is possible by means of an inverter installed on the machine which allows wings speed control and the possible timed inversion of the blades and of the mixing as well.

For both models it's available (on request) an electric fan to supply the Silo quickly and automatic (electric Hurricane 315) and/or a special device with load cells that allow to weight the quantity of material inside the Silo. In addition, the Silo can be part of our complete line of fiber processing and filling pillows along with CombyCat and / or Combyball, Grizzly, CombyMove, etc..

TECHNICAL CHARACTERISTICS:

Dimensions on floor: 125 x 250 cm

Max. dimension: 280 cm

Height: 285 cm

Loading volume: 5,5 mc approx.

Working: electric 400V - 50/60 Hz

Motors: 1 Motor 0,75 Kw

1 Motor 1,5 Kw

1 Electric fan 1,1 Kw

Safety devices

For XPERFORM model:

1 Inverter Threephase 400V / 1,5 Kw

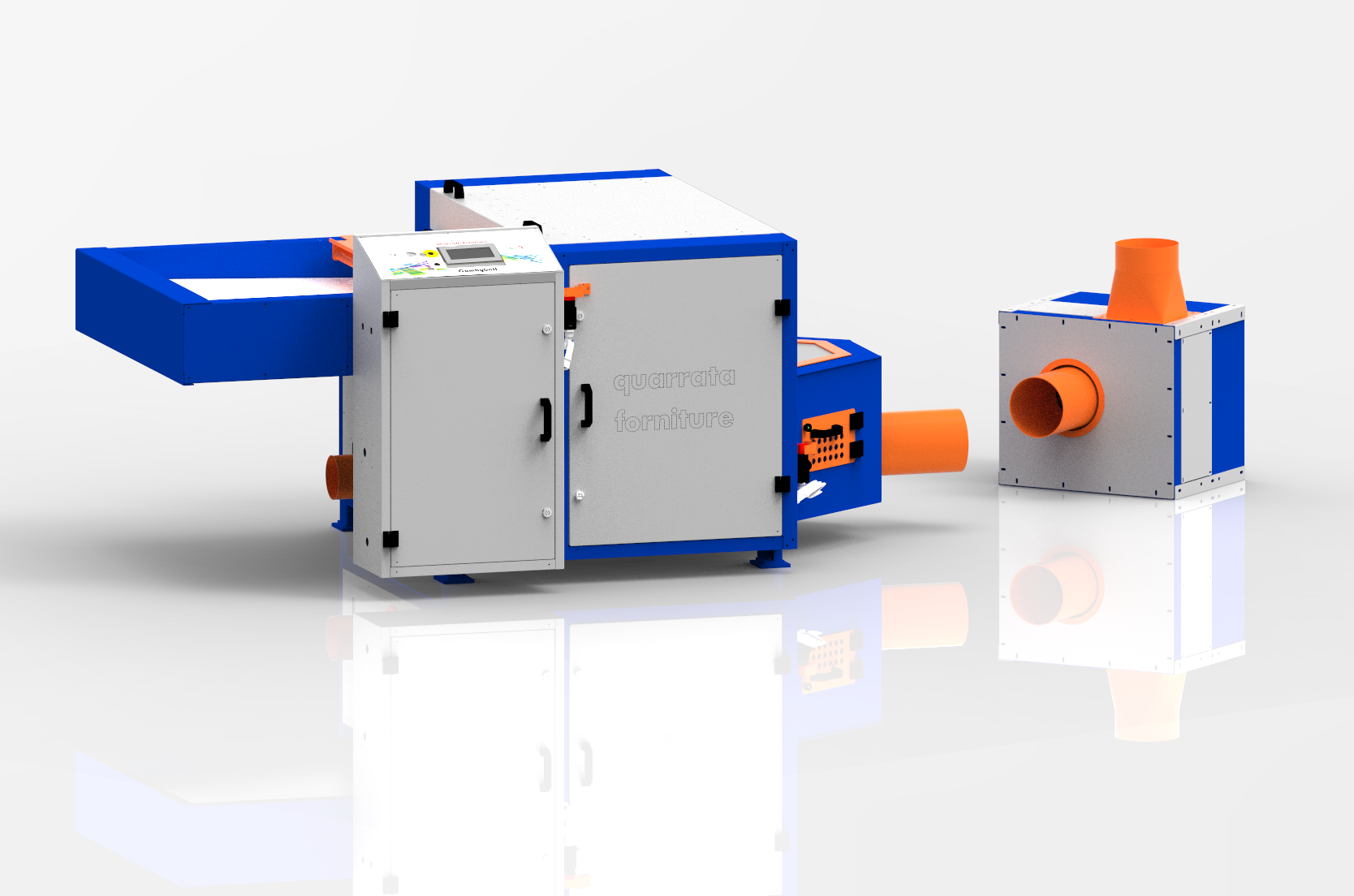

Comby Ball

The Comby Ball machine produces fiber balls from staple fiber in bales.The use of fiber balls, instead of regular carded fiber, allows to save between the 25% and the 30% of the material, since the balls are more elastic, with a better weight\volume ratio. Furthermore the balls better resist to the squashing thus the lifetime and the quality of the final product will increase.

It has a capacity of approximately 200\300 kg per hour and is able to process both 32mm and 64mm polyester fibers. The machine can be manually fed or is possible to add another machine (Combymove, bale opener machine) to automatize the feeding process.

Through its electrical ventilator - included with the machine - the outcome flows toward the storage (Silo)

CombyBall is a safe and user friendly machine which perfectly matches in every factory layout and always assures high performances.

TECHNICAL CARACHTERISTICS:

Dimensions: 280 x 160 cm

Height: 120 cm

Weight: 1100 kg

400 V Three Phases (8kw) - 3

Motors

Production Capacity: 200/300 kg/h